A Detailed Explanation of the Water Cement Ratio

A water-cement ratio indicates how much water is used to make a concrete mixture compared to how much cement is used. The Strength of concrete largely depends on the ratio of cement to water.

It is also responsible for the porosity of hardened cement paste because of the ratio between water and cement. A proportion of water to cement is required for proper workability. For water to make contact with all cement particles, the cement ratio needs to be about 0.3. That will allow the cement paste to hydrate completely.

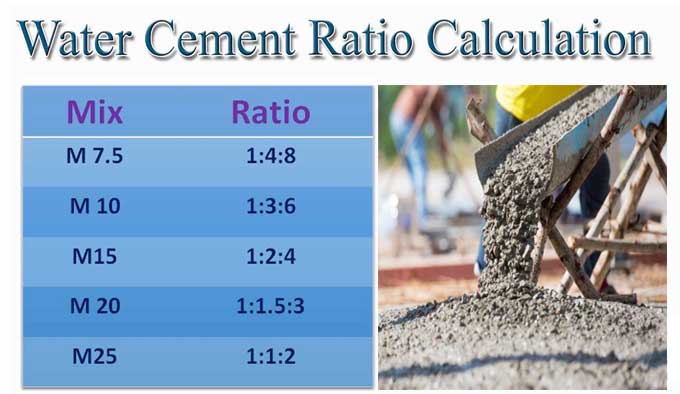

Calculation of Water Cement Ratio

- Calculate the Water quantity for concrete by first finding the cement content.

- Assuming a volume of 50kg of cement is needed.

- Volume of cement x Water/Cement ratio = required amount of water.

- So a 50 kg cement bag needs 25 liters of water x 0.5 kg cement bag.

- Workability and strength requirements will impact the ratio of Water/Cement in the Design Mix.

Role of Water in Concrete

Concrete contains micro components like cement, sand, fine aggregates, and coarse aggregates. If you want to produce a block of concrete that has a compressive strength that meets our expectations, then you must combine these materials with the correct amount of admixture.

Water now adds to the cement by adding 23% to 25% of the volume to initiate the chemical process. Concrete voids fill with a 15% paste of cement and water called a gel, which starts the chemical process.

Effects of too much water in Concrete

The chemical process of cement requires 23% of water. Water cement will lose its strength when more water is added. The concrete will settle down if too much water adds to increase its workability. The evaporation of water leaves lots of voids in concrete that reduce its strength.

Concrete Workability use for Water Cement Ratio

Concrete's workability refers to its ability to be handled, transported, and positioned without being segregated during the job. Workable concrete can be handled, positioned, and transported without causing any separation during the installation process.

Benefits of Water in Concrete

- Increased strength is one of its benefits.

- The material is more resistant to weathering.

- Dries quickly and shrinks less.

- Volume changes less when wetted and dried.

- The permeability is lower.

- This improves the bond between reinforcement and concrete.

Importance of Water in Concrete

The two most important ingredients that influence the properties of concrete are cement and water. Cement and water are the main ingredients that bind everything together. The water-cement ratio of concrete determines its strength and durability after curing. When the ratio of Concrete to Water is 0.40, then 40 water pounds should be added for every 100 pounds of cement.

Impact of Water on Concrete at low or high levels

- Concrete can shrink, crack, and lose strength when water adds too much. Concrete that is too wet is difficult to work with, and it can suffer from segregation and bleeding issues.

- Concrete will be hard, difficult to compact, and stiff without enough water, and it will develop honeycombs. Moving concrete is more difficult.

Conclusion

Concretes with low water-cement ratios have the advantage of being considerably more sustainable than concretes with high water-cement ratios, as their use implies a lot less concrete being mixed, transported, and poured to support a given load.

Concrete is essentially made strong by the proximity of the cement particles within the paste.

The structure may crack prematurely if low water content concrete doesn't receive a proper water cure, which impedes the development of plastics and can result in long-term durability issues.

Water curing can be enforced if the contractors are profitable. It only takes to make the activity profitable for them. You must provide detailed instructions for water curing, and you must pay separately for each one.