Water Cement Ratio in Mix - W/C Ratio Calculation

Have you been told "Include some water, the concrete looks exceptionally hard"? Is this right? Including more (Water Cement Ratio) at the site level to expand the concrete functionality? In no way, shape or form.

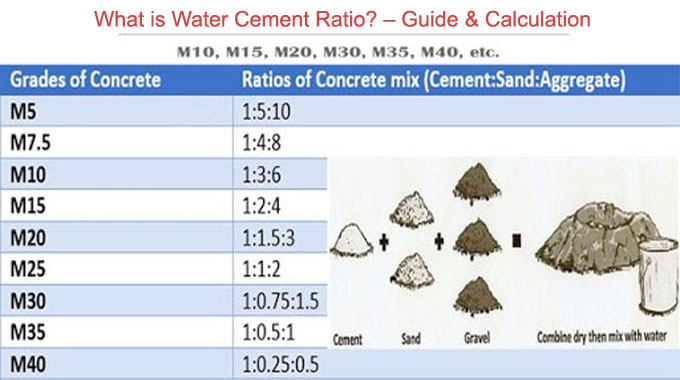

Water Cement Ratio implies the ratio between the weight of water to the weight of cement utilized in concrete mix. Typically water cement ratio falls under 0.4 to 0.6 according to IS Code 10262 (2009) for ostensible mix (M10, M15 ... M25)

We as a whole realize that the water cement ratio will straightforwardly influence the quality of concrete. It is possible that it expands the quality whenever utilized to the right extent or lessens it. In any case, have you ever considered why we are utilizing water on the off chance that it has so much trouble?

Role of Water in Concrete

Concrete is a macro content. It contains micro fixings, for example, cement, sand, fine total and Coarse total. So as to secure high quality concrete which withstands up to our ideal compressive quality, We need the right extent of admixture to consolidate these materials.

Here comes the Water which will start this substance procedure by including 23%-25% of the cement volume. This starts the substance procedure and makes 15% of water cement glue otherwise called a gel to fill the voids in the concrete.

Impacts of an excess of water in concrete

As expressed above we need 23% of water to start the substance procedure on cement. Including more water than this permissible Water cement breaking point will really influence the quality. In the event that we continue adding water to build the functionality, at that point the concrete has bunches of liquid materials where the totals will settle down.

When the water vanishes it leaves heaps of voids in concrete which influences the concrete quality.

In any case, on the off chance that we follow the rules so as to keep up the quality of the concrete then it will influence the concrete functionality and make it difficult to deal with and place them.

Hold up a moment. Do you realize what Workability Of Concrete?

Workability implies the capacity of concrete to deal with, transport and putting with no isolation. The concrete said to be serviceable on the off chance that it very well may be handily taken care of, set and shipped with no isolation while setting it in site. That is the reason we are utilizing plasticisers and superplasticizers which will expand the functionality without influencing the W/C Ratio.

W/C Ratio Calculation

We don't really figure the Water Cement Ratio. It is chosen from different usefulness tests dependent on the basic individuals, concrete quality, transportation, determination of total and so on. At Site Level, we can utilize the Water Cement Ratio IS 10262 (2009) Code Chart for the ostensible mix. It is a guide so make your own judgment.

Estimation of Water Quantity for Concrete

As should be obvious from the Chart, the W/C Ratio shifts from 0.4 to 0.7 contingent upon introduction conditions. On the off chance that we have to figure Water amount for concrete, first discover the cement content for the volume.

Provided that we Assume the necessary cement volume as 50kg,

Required measure of water = W/C Ratio X Cement Volume

Subsequently, Required measure of water = 0.5 X 50 kg = 25 liters/50 kg cement sack.

For Design mix, the W/C Ratio will rely on the usefulness, quality necessities. In IS 10262-2009 ANNEX A. they have clarified the procedure for configuration mix. Expectation that causes you.

Water Cement Ratio Test

We trust now you have a considerable measure of information on the Water Cement ratio in the concrete mixes. The time has come to test this indispensable undertaking. How to test water cement ratio? We really utilize Concrete Slump Test at the site level to check this functionality and Consistency. This is talked about in another post on our site.