A Calculation of the Slump Cone Volume in Construction

Slump tests are conducted to determine how consistently the concrete in each batch works. Concrete consistency refers to how workable or fluid it is when newly made, so it measures the relative ease with which concrete flows.

Concrete slump tests are very useful for monitoring the degree of fluidity of the concrete mix or the workability of concrete on-site. Concrete of the same consistency may vary in its workability, especially if it is loose and wet.

The tests also demonstrate changes in fluidity between two batches of mixes. In construction, a few simple instruments and simple procedures commonly used to test slumps. Plasticizers also test for their effects on slump results via the slump test.

Slump Cone Test

A conical cone with both ends open uses in the Slump Cone test. When the slump cone fills with concrete raises and the resulting concrete level spreads over the surface, it indicates how fluid, workable, and consistent the concrete mix is. The test also indicates the water amount added was correct.

Measurement

The slump cone test method can be used to measure the slump value of concrete. It fills with fresh concrete until the top reaches. That is done by lifting the cone gently and measuring the difference between the cone's top and the top concrete fall.

Apparatus

Conical-shaped testing devices known as slump cones and Abrams cones are used, which has both ends open and a handle attached. Its internal diameter measures in millimeters. This cone is about 300 mm tall, with a top diameter of 100 mm and a bottom diameter of 200 mm.

Procedure

- That accomplishes by placing the slump cone on a hard surface, such as metal or concrete that is not water-absorbing.

- Three layers of concrete poured into the Slump cone.

- It is required to tap each layer of the concrete mix using a bullet-shaped metal rod 16 mm in diameter and 6 inches long.

- It is necessary to remove extra concrete from the top of the cone after filling the last layer.

- Using both hands, he quickly lifted the slump cone upward. There is then no barrier to prevent the concrete from falling.

- Slump is the height at the end of free fall, and it is measured to the nearest 5 millimeters if it is 100 millimeters.

Calculation

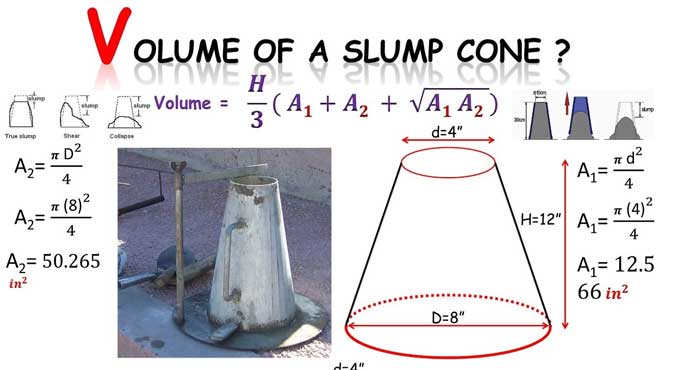

[(h ? 3) ? {A1+A2 + vA1? A2}]

This formula calculates the volume of the slump cone, where the slump cone's height is h.

The area of the top circular surface is A1 & A2 is the area of the bottom circular surface.

This slump cone has a height of 300mm. =0.3m.

D1 is the diameter of the top surface, 100mm=0.1m.

D2 is the diameter of the bottom surface is 200mm. =0.2m.

A1 and A2 are the two areas you need to calculate first.

A1 = [(p ? D12) ? 4]

= [(3.142 ? 0.12) ? 4]

= [0.03412 ? 4]

= 0.007855 m2.

A2= [(p ? D22) ? 4]

= [(3.142 ? 0.22) ? 4]

= [0.12568 ? 4]

= 0.03142 m2.

Slump Cone Volume

= [(h ? 3) ? {A1+A2 + vA1? A2 }]

= [(0.3 ? 3) ? {0.007855+0.03142 + v0.007855? 0.03142}]

= [(0.1) ? {0.039275 + v0.0002468}]

= [(0.1) ? {0.039275 + 0.01571}]

= [0.1 ? 0.054985]

= 0.00549 cubic meters or 0.1939 cubic feet.

Precautions

When aggregate is greater than 40 mm, the slump test is not applicable. Concrete that is stiff and high dry cannot accurately test by this method.

Benefits

A simple apparatus makes it possible to perform the test in the laboratory as well as on-site. Compared to other tests, it requires fewer apparatuses. Results are given too quickly due to short testing times.

Types of Slump Cone

Sheer Slump

Concrete shears and slips are subjected to shear slumps.

Collapse Slump

Concrete collapses completely in a collapse slump.

True Slump

Concrete simply subsides in a slump, keeping its shape more or less.

The test should be repeated if a shear or collapse slump is observed. The test can only be used if there is a true slump.

To get more details, watch the following video tutorial.

Video Source: Engineer Boy