Usefulness of recycled concrete aggregates

Concrete recycling is gaining popularity since it safeguards natural resources and removes the requirement for disposal with the use of the instantly accessible concrete as an aggregate source for new concrete or other applications.

Recycling of concrete is a comparatively an easy method. It includes the steps like breaking, removing, and crushing existing concrete into a material with a particular size and quality. The quality of concrete with RCA is based on the quality of the recycled material utilized.

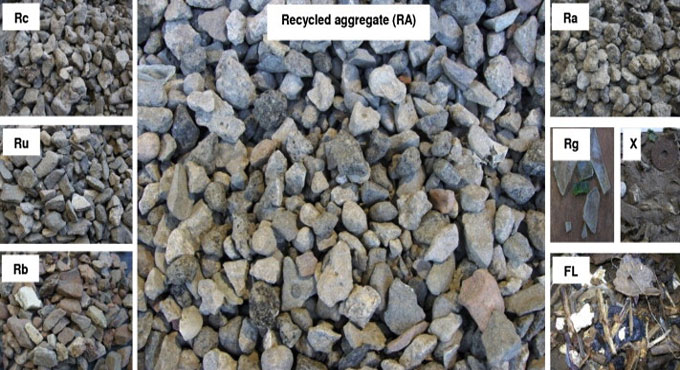

Reinforcing steel and other embedded objects, if any, should be eliminated, and check carefully to resist impurity provided by other materials which range from asphalt, soil and clay balls, chlorides, glass, gypsum board, sealants, paper, plaster, wood, and roofing materials.

Common uses devoid of processing:

? several types of general bulk fills

? Bank protection

? Base or fill for drainage structures

? Road construction

? Noise barriers and embankments

Most of the unprocessed crushed concrete aggregate is available as 1? inches or 2 inches fraction for pavement sub bases.

Once the contaminants are eliminated through particular demolition, screening, and /or air separation and size cutback in a crusher to aggregate sizes, crushed concrete are applied as new concrete for pavements, shoulders, median barriers, sidewalks, curbs and gutters, and bridge foundations structural grade concrete soil-cement pavement bases lean-concrete or econo-crete bases and bituminous concrete.

Properties Of Recycled Aggregate: The crushing properties of solidified concrete have similarity with those of natural rock and are not considerably impacted by the grade or quality of the original concrete.

Recycled concrete aggregates created from all but the substandard quality original concrete is expected to pass the same tests necessary for traditional aggregates.

Recycled concrete aggregates comprise the original aggregates as well as hydrated cement paste. This paste minimizes the specific gravity and raises the porosity with regard to similar virgin aggregates. Greater porosity of RCA causes a higher absorption.

Mix Design: It is normally found that when natural sand is applied, up to 30 percent of natural crushed coarse aggregate is substituted with coarse recycled aggregate devoid of majorly impacting any of the mechanical properties of the concrete.

Since replacement amounts raise drying shrinkage and creep will be raised and tensile strength and modulus of elasticity will be reduced. The compressive strength and freeze-thaw resistance are not impacted considerably.

Sustainability: Recycling concrete maintains sustainability various ways. The simple act of recycling the concrete minimizes the amount of material that should be land filled. The concrete itself is changed to aggregate and any embedded metals are also eliminated and recycled. Since the space for landfills turns to premium, it aids in minimizing the requirement for landfills as well as decreases the economic impact of the project. Besides, when recycled concrete aggregates are used, they reduce the requirement for virgin aggregates. This sequentially minimizes the ecological impact of the aggregate extraction process. By eliminating both the waste disposal and new material production requirements, transportation requirements for the project are minimized considerably.