Some useful tips on grout placement

This construction article sheds light on the types of grouting materials, pre-grouting steps and grouting inspection method & other vital steps.

Non shrink structural grout should be transported to the construction site in bags and obtained, preserved and managed as per the method of Receipt, Storage and Handling of Products. Particularly, bagged grout should be preserved according to storage requirements. Any nonconforming items should be passed on in compliance with procedures.

Construction QA/QC team shall be given the opportunity to review manufacturer?s literature, including compressive test results, Before placing the grout on the construction site, the manufacturer?s literature along with compressive test results should be examined by the QA/QC team.

The contractor should submit his processes, proposed vendors and manufacturer?s literature together with the suggested plan for placement to QA/QC for appraisal before first placement.

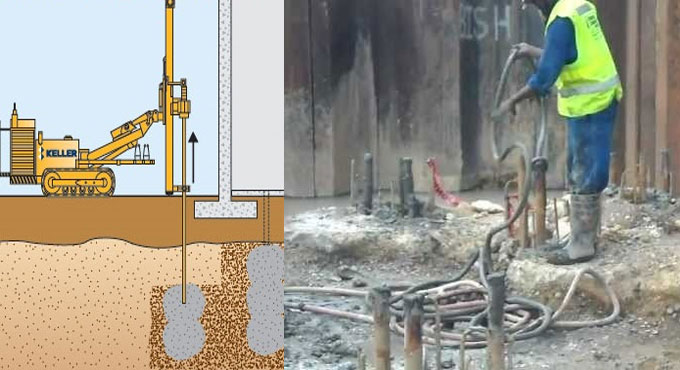

Grout Placement Method: Non shrink grout should be blended, placed, cured and examined in compliance with the suggestions of the manufacturer and/or job site specifications and methods.

Key Inspection Attributes:

Given below, some major inspection items which should be examined and/or verified in the context of grout placement activities :-

? Ensure that the grout satisfied the requirements of the job with respect to proposed use, necessary compressive strength and applicability.

? The date on the grout bags should be checked properly to make sure that the grout has not passed the suggested shelf life.

? Check the concrete foundation where the grout will be applied is cleansed properly, roughened and soaked with water for 24 hours before placing grout.

? Ensure that the grout is blended according to manufacturer?s literature. It is suggested that a test batch should be mixed before the first production placement to check that the needs are fulfilled for workability and compressive strength.

? Check the temperature of the mixed grout to make sure that the compliance follows the specifications and/or manufacturer?s literature. In order to control the temperature of mixed grout, ice water or hot water should be used.

? Ensure that grout forms are built up to allow quick, incessant arrangement and complete filling of the space to be grouted.

? Check that the form on the grout placing side is erected at a 45? based on the size of the grout placement.

? Check that for arranging the large grout, metal bands or straps are provided under the base plates to allow shifting grout into complicated zones. These should be utilized after getting approval from the grout manufacturer.

? Ensure that grouting only continues from the grout placing side of the form to get rid of the entrapment of air pockets.

? Ensure that all necessary testing is performed compliant with specifications. Normally, non-shrink grout cubes should be formed, cured and examined in reference to the Project specification and should be noted on a form.

? Check that the grout is cured with regard to manufacturer?s recommendations and/or specifications.