Know everything about Stirrups in Construction

What are Stirrups in Construction?

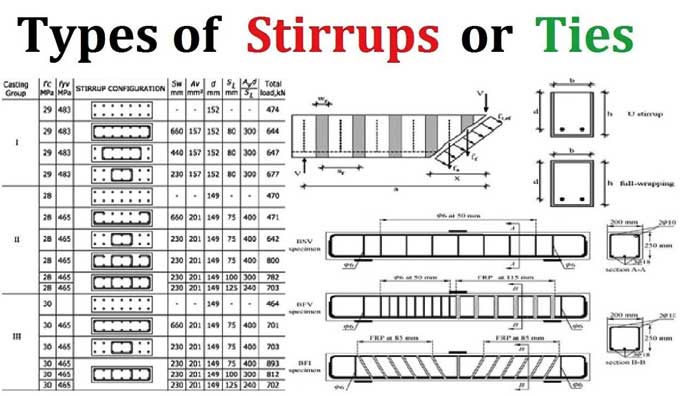

A Stirrup is a complete circuit of reinforcing bars that are used to hold the main Reinforcement Bars together. Stirrups come in a range of shapes and sizes, depending on the structures? design and shape. Stirrups are usually made of steel and wrapped around the top and bottom bars of beams or columns. Stirrups are used to keep reinforcing bars in place. Stirrups are needed to keep the columns and beams from buckling and to help with lateral stress resistance e.g. earthquake.

Stirrups are normally perpendicular to the longitudinal direction of reinforcement bars, but they can also be positioned diagonally. This is done to avoid shear failure, which occurs frequently in the case of beam fractures.

Stirrups are utilised to better manage shear capacity. The stirrup spacing along the beam is crucial, and the designer should define it if possible.

Stirrups are used to keep things in the same direction. Stirrups aid to maintain order while also adding strength to the structure at vital spots where it is likely to be vulnerable over time.

What are the Purposes of using Stirrups in construction?

- When large cracks in the vertical direction line up and the concrete cube split, this is known as ultimate load failure. The expansion of concrete in lateral directions causes vertical cracks to form. As previously demonstrated in studies, if the concrete is limited in lateral directions, the creation of vertical fissures is hampered. As a result, as the failure strain increases, the concrete strength increases.

- Bridge columns are frequently designed using the theory above. Around the vertical primary reinforcement, steel stirrups are inserted. It helps to reduce lateral deformation of the interior concrete core, which increases the strength of a substantial column and its sheer reinforcement function.

- Open stirrups are used in places where the effect of torsion is minimal, primarily to resist shear stresses in concrete beams. U-shaped stirrups are used to prevent shear cracks on the tension side of concrete beams. Closed stirrups should be utilized instead when concrete beams are designed to withstand a significant amount of torsion.

- The stirrup is frequently not prefabricated, and the installer attempts to create the stirrup in the field after the horizontal bars have been installed. Because the stirrup is made up of two sections with a poor lap splice, this is frequently evident. Installing a stirrup at the same time as the horizontal reinforcement is significantly easier and more efficient.

What are the advantages of using Stirrups in construction?

- Stirrups are installed at appropriate intervals between beams to prevent deformation and shear failure.

- Stirrups are occasionally arranged diagonally and are frequently put vertically. This is done to avoid shear failure, which is often diagonal in the case of beam fractures.

- To keep their placements, the main bars are restrained by transverse steel tie bars.

- It boosts the structure's load-bearing capacity.

- It prevents primary reinforcement movement during the concrete pour.

- Stirrups are weaker than reinforcing steel. Stirrups, on the other hand, are widely applied in combination with rebar. While rebar serves as the concrete's backbone, stirrups help the rebar stay straight and offer additional support to the concrete column in which it is installed.

- They keep RCC structures from collapsing in the event of a seismic event, such as an earthquake.

- It also aids in maintaining and obtaining a consistent transparent coating over its whole length.

- Stirrups are required to keep the columns and beams from buckling.

To get more details, watch the following video tutorial.

Video Source: Civil Engineers