Step-by-step process for designing a septic tank

In this construction article, you will learn the process to make the design of any septic tank.

Design of Septic Tank: The capability of septic tank is mainly based on the number of peoples who use the tank as well as intermission of dirt extraction. Generally, dirt should be discharged frequently after 2 years. The capability of tank for storing liquid is taken as 130 liters to 70 liters per head. For less number of users, 130 ltr per head is ideal.

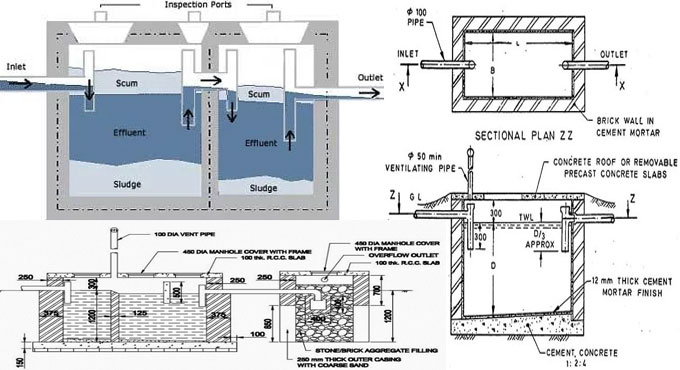

A septic tank is normally built up with brick wall that contains cement mortar having density [not below 20cm (9 inch)] and the foundation floor made of cement concrete in 1:2:4 ratio. Both internal and external surfaces of the wall and top of the floor are plastered with thick cement mortar 1:3 mix that contains least density of 12mm (one-half inch).

All the corners of septic tank located inside are rounded. Water proofing agent like Impermo, Cem-seal or Accoproof etc. is included to the mortar at the rate of 2% of the cement weight. Water proofing agent should be included by maintaining the same ratio in the concrete as well as forming the floor of the tank.

To simplify the process for collection and elimination of the dirt, the floor of septic tank is supported with a slope of 1:10 to 1:20 in the direction of the inlet side. It signifies that floor of the outlet side will be on the higher elevation as compared to the floor at inlet side.

Dimensions of Septic Tank Components

i) Length, Width and Depth of Septic Tank

Width = 750mm(min)

Length = 2 to 4 times width

Depth = 1000 to 1300mm. (min below water level) + 300 to 450mm free board

Maximum depth = 1800mm + 450 mm free board

Capacity = 1 cubic meter (10 cubic feet) minimum

ii) Detention period: In the process of designing the septic tank, detention period should have been 24hrs. The rate of flow of waste matter must be identical to the rate of flow of influent.

iii) Inlet and outlet pipes: An elbow or T pipe with 100mm diameter is submerged to a deepness of 250-600mm underneath the liquid level. For outlet pipe an elbow or T type of 100mm diameter pipe is submerged to a deepness of 200-500mm underneath the liquid level. Select the pipes which made of stone ware or asbestos.

iv) Baffle Walls of Septic Tank: For the tanks small in size, RCC hanging type scum baffle walls are set in septic tanks. Baffle walls are arranged adjacent to the inlet. It is non-compulsory near the outlet.

The inlet baffle wall is set at a gapping of L/5 from the wall, where L denotes the length of the wall. The baffle wall is normally expanded 150mm above to scum level and 400-700mm under it.

Scum being light, normally floats at the water level in the tank. The density of the wall fluctuates from 50mm to 100mm. In the lower part of bigger tanks, there are holes for discharging sludge.

v) Roofing Slab of Septic Tank: Based on the size of the tank, RCC slab having density of 75-100 mm is provided on the upper portion of the septic tank. Circular manholes with 500mm clear diameter are arranged for inspection and desludging. For rectangular opening, clear size is maintained as 600X450mm.

vi) Ventilation Pipe: The cast iron or asbestos pipe having 50-100mm diameter is arranged as outlet to discharge polluted gases and for ventilation. The pipes should be expanded 2m (min) over ground level. A mosquito proof wire mess or cowl is arranged on the upper part of the ventilation pipe.