Some useful tips to use cement plaster on wall surface

Generally, cement plastering is done by providing coating for outside and inside surface of wall. Cement plaster is normally applied with a single coat or double coat. Double coat plaster is suitable where depth of plaster remains in excess of 15 mm or when it is necessary to maintain a very fine finish. The following process is undertaken to apply a double coat cement plaster on wall surface.

Step 1 - Arrangement of surface for plastering

Step 2 - Foundation for plaster

Step 3- Providing first coat (or under coat or rendering coat)

Step 4 - Providing second coat (or finishing coat or fine coat)

DETAIL PROCESSES FOR CEMENT PLASTERING:

Step 1: Arrangement of surface for plastering

1. Maintain all the mortar joints of wall rough in order to provide a perfect bonding to retain plaster.

2. Cleanse all the joints and surfaces of the wall by applying a wire brush. The surface of the wall should be free from any oil or grease etc.

3. In case the surface is smooth or the plastering is too old, then rake out the mortar joint to a depth of at least 12 mm to give a better bonding to the plaster.

4. If the projection on the wall surface surpasses 12 mm, then knock it off, in order to keep a consistent surface of wall. It will help in minimizing the consumption of plaster.

5. If there is any cavities or holes on the surface, then it should be filled with proper material beforehand.

6. Rough up the complete wall for being plastered.

7. Clean the mortar joints and whole wall to be plastered, and it should be drenched for minimum 6 hours prior to use cement plaster.

Step 2: Foundation for plaster

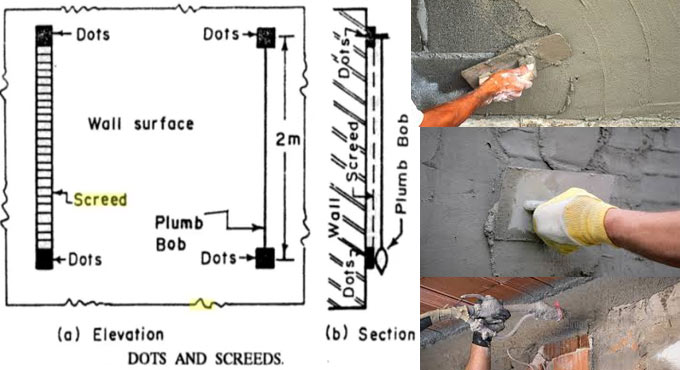

1. Initially, make the wall dotted to maintain consistent thickness of plastering all through the wall surface. A dot signifies patch of plaster having size 15 mm * 15 mm and thickness of about 10 mm.

2. At first the dots are set on the wall horizontally and then vertically maintaining a space of about 2 meters covering the complete wall surface.

3. Examine the verticality of dots, one over the other, with the use of plumb-bob.

4. As soon as the dots are set, the vertical strips of plaster, called as screeds, are developed among the dots. These screeds perform as the gauges for keeping up smooth thickness of plastering being used.

Step 3: Providing first coat (or under coat or rendering coat)

1. For brick masonry, the depth of first coat should be normally 12 mm and in case of concrete masonry this thickness differes from 9 to 15 mm.

2. The proportion of cement and sand for first coat plaster fluctuates from 1:3 to 1:6.

3. Apply the first coat of plaster between the spaces formed by the screeds on the wall surface. This is done by means of trowel.

4. Level the surface with flat wooden floats and wooden straight edges.

5. As soon as level is completed, left the first coat to set but not to dry and then roughen it employing scratching tool to develop a key to the second coat of plaster.

Step 4: Providing second coat (or finishing coat or fine coat)

1. The depth of second coat or finishing coat fluctuates among 2 to 3 mm.

2. The proportion of cement and sand for second coat plaster fluctuates from 1:4 to 1:6.

3. Prior to use the second coat, wet the first coat consistently.

4. Provide the finishing coat with wooden floats to an uniform surface and the proper finishing should be done with wooden floats.

5. Try to apply the finishing coat from top towards bottom and complete in one operation to get rid of joining marks.

As soon as the plastering work is completed, it should be kept drenched by sprinkling water for minimum 7 days to maintain strength and rigidity.