Advantages and Disadvantages of Concrete Slump Test

The concrete Slump test gauges the consistency of new concrete before it sets. It is performed to check the functionality of newly made concrete, and along these lines the simplicity with which concrete streams. It can likewise be utilized as a pointer of an inappropriately blended group. The test is well known because of the effortlessness of device utilized and basic strategy. The Slump test is utilized to guarantee consistency for various heaps of concrete under field conditions.

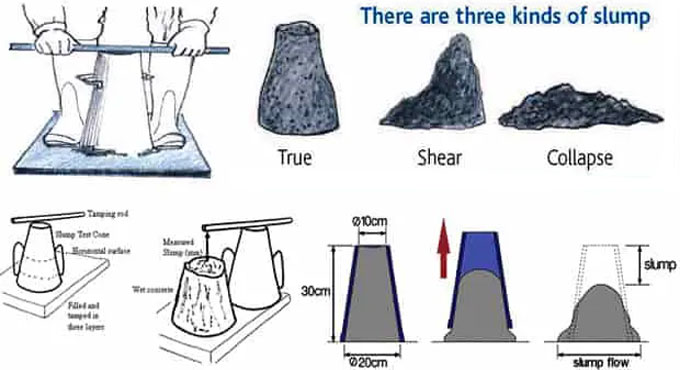

How to perform a Concrete Slump Test

The test is done utilizing a metal form looking like a funnel shaped frustum known as a Slump cone or Abrams cone, that is open at the two finishes and has appended handles. The apparatus ordinarily has an interior width of 100 millimeters (3.9 in) at the top and of 200 millimeters (7.9 in) at the base with a statue of 305 millimeters (12.0 in).

The cone is put on a hard non-spongy surface. This cone is loaded up with new concrete in THREE phases. Each time, each layer is packed multiple times with a 2 ft (600 mm) long slug nosed metal pole estimating 5/8 in (16 mm) in diameter.

At the finish of the third stage, the concrete is hit off flush with the head of the shape. The shape is deliberately lifted vertically upwards, so as not to upset the concrete cone.

Pros of Concrete Slump Test

1. Slump test is simple and basic. A non-specialized individual can perform it with no issue.

2. It is valuable to check the group to cluster or hour to hour variety in the materials which will be taken care of into the blender. Increment in Slump implies dampness substance of total has expanded out of the blue or insufficiency of fine total has changed. Excessively high or too low Slump is a pointer of unwanted usefulness of concrete and blender administrator gets an admonition to discover an answer to cure the issue.

3. This test doesn't require any exceptional exorbitant gear. The example isn't required to be sent to a lab. It tends to be done in the development territory.

4. Slump test doesn't request a long-lasting period to get the outcome. In the event that we contrast and compress a quality test, it requires close to 30 days to get the outcome yet we can get Slump an incentive inside certain minutes.

5. Slump test is simple and basic. A non-specialized individual can perform it with no issue.

6. It is valuable to check clump to cluster or hour to hour variety in the materials which will be taken care of into the blender. Increment in Slump implies dampness, substance of total has expanded out of the blue or lack of fine total has changed. Excessively high or too low Slump is a pointer of bothersome functionality of concrete and blender administrator gets an admonition to discover an answer to cure the issue.

7. This test doesn't require any unique exorbitant gear. The example isn't required to be sent to a research facility. It tends to be done in the development zone.

8. Slump test doesn't request a long-lasting period to get the outcome. In the event that we contrast and compressive quality test, it requires close to 30 days to get the outcome however we can acquire Slump an incentive inside certain minutes.

Cons of Concrete Slump Test

1. It is untrustworthy for lean blends. In a lean blend, a genuine Slump may change over into shear or breakdown without any problem. Generally variety can be found from one example of lean blend and it tends to be an extraordinary disarray to decide the specific outcome.

2. It isn't definite estimation since Slump bears no one of a kind connection to functionality. Indeed, for various sorts of totals, a similar Slump can be recorded for various usefulness. We ought to likewise remember that Slump doesn't gauge the simplicity of compaction. The Slump happens under oneself load of concrete just, it doesn't speak to conduct under different conditions like vibration, getting done with, siphoning or traveling through a tremie.

3. For an example, beyond what one shape can become about confounding the right outcome. In the event that shear Slump happens, it might achieve genuine Slump in the next test.

4. It can't separate the usefulness of firm blends as it shows zero Slumps. In dry range, no distinction can be identified between various blends in with various usefulness.

5. It isn't appropriate for concrete shapes of total higher than 40 mm.

6. It is questionable for lean blends. In a lean blend, a genuine Slump may change over into shear or breakdown without any problem. Generally variety can be found from one example of lean blend and it tends to be an extraordinary disarray to decide the specific outcome.

7. It isn't precise estimation since Slump bears no one of a kind connection to usefulness. Indeed, for various kinds of totals, a similar Slump can be recorded for various usefulness. We ought to likewise remember that Slump doesn't quantify the simplicity of compaction. The Slump happens under oneself load of concrete just, it doesn't speak to conduct under different conditions like vibration, getting done with, siphoning or traveling through a tremie.

8. For an example, beyond what one shape can become about confounding the right outcome. In the event that shear Slump happens, it might achieve genuine Slump in the next test.

9. It can't separate in functionality of firm blends as it shows zero Slumps. In dry range, no distinction can be recognized between various blends in with various functionality.

10. It isn't appropriate for concrete shapes of total higher than 40 mm.