Discover the Importance of Shoring in the Construction Industry

Shores support buildings, vessels, structures, and trenches that are at risk of collapsing or need repair. In a nutshell, shores are timber or metal props. If there is an uneven settlement in a wall or a crack in a wall, the entire wall may need to be lower, or parts of the wall need to open up. These cases involve shoring.

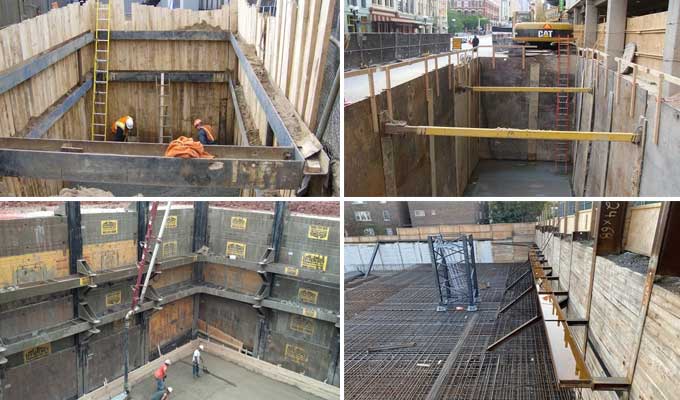

Site Surveying for Shoring

To determine the load location and shore number, the surveyor must carefully examine the site. Soil and floors have a bearing capacity & map of the underground services which should avoid or bridge.

Types of Shoring

Raking Shoring

A system consisting of sloping struts or rakers distribute the load from the walls and floors to the ground. For rakers to receive the maximum load from walls and floors, they must position correctly.

Workflow of Raking Shoring

- A wall plate must mark and cut with mortises and housings.

- Prepare external walls by drilling needle holes.

- Lay the grillage platform and soleplate on firm-bearing subsoil.

- Prepare the bottom shore for raking by cutting and erecting rakers. The heel is cut so that the rakers can be levitated down the soleplate using a crowbar, thereby tightening the shore. To avoid reaching the tangent point and not make levering impossible, the angle between the soleplate and shores should be less than 90 degrees.

- The shores should be braces and cleats, distance blocks, bindings, and, if necessary, cross-bracing should install.

Flying Shoring

A raking shore provides the same function a shoring shore has the advantage of providing a clear working area underneath the shoring. As long as there is no span greater than 12.000 meters when the arrangement becomes uneconomical, the walls can use between any parallel surface.

A single horizontal member uses for a span up to 9000 m. While for larger spans, two horizontal shores are necessary to keep the section sizes within the commercially available range.

Double Flying Shoring

It is possible to build up the principal members of all types of shoring from smaller sections, ensuring that all butt joints are separated to ensure adequate rigidity using bolts and timber connectors. Construction in this way is similar to laminate timber construction. As with raking shoring, fly shoring requires the same site operations as raking shoring.

Dead Shoring

Vertically downward dead loads act on this type of shoring. Some shore legs will include a soleplate, head plate, and means to adjust the shore, while other versions will include a vertical prop.

A horizontal beam or needle connects two shore legs over their heads in a usual arrangement. The needle transfers loads down to the shore legs and then to a solid bearing surface. It may be necessary to remove pavings and cut suspended timber floors to obtain a suitable bearing surface. It is not possible to manipulate a shore leg through two stories if a basement encounters.

Importance of Shoring

Structures in which there is a perceived risk of collapse and danger to any person on or nearby the site are subject to these restrictions. There are also provisions in the Work that pertain to risk assessment. It can stay in place for a considerable time even though it is an interim measure while a permanent support structure constructs.

The importance of these factors in construction cannot rule out. When assembled, dismantled, or demolished, the system must remain under the supervision of a competent person for the duration of the process.

Benefits of Shoring

- Supporting dangerous or at-risk walls from subsidence, bulging, or leaning.

- If a basement is building near a sound wall, removing the underlying support will avoid sound walls failing.

- An adjacent building or structure needs support.

- When the lower portion of a wall forms into an opening, the upper portion supports.

- To permit the removal of a support wall and the replacement by a beam to a floor or roof.

- Structural softwood is the most common material used for moorings since it is both stronger and lighter than steel while also being more versatile than steel.

- In addition, scaffold tubular can form a shoring arrangement.

To get more details, watch the following video tutorial.

Video Source: The Structural World