What is Prestressed and difference between Pre-Tensioning and Post-Tensioning

Prestressed Concrete: In normal strengthened concrete, elastic worries by steel alone and compressive anxieties are taken up by concrete. This concrete beneath the unbiased axis is disregarded since it is frail in tension.

In spite of the fact that steel takes up to the elastic anxieties, the concrete at the malleable zone creates minute breaks. The heap conveying limit of such concrete areas can be expanded if steel and concrete both are worried before the use of external burdens.

This is the idea of prestressed concrete. According to the ACI board of trustees, prestressed concrete is that concrete wherein internal worries of reasonable size are presented with the goal that these anxieties coming about because of the external loadings can be checked to an ideal degree.

In RCC members, prestress prompted is of compressive nature with the goal that it adjusts the ductile anxieties created because of external burden. It makes the entire segment viable (the concrete region in the tension zone additionally) in opposing burdens.

Strategies for Prestress: Prestress might be initiated in the structure by different prestressing strategies. Some of which are clarified underneath.

Internal Prestressing:

1. In this framework, a prestressing power is applied to the high elastic steel, i.e., the steel fortification.

2. It prompts internal compressive worries in concrete.

3. This most usually utilized technique due to the simple and exact application.

4. Internal prestressing should be possible by two distinct strategies : Pre-tensioning and Post-tensioning

External Prestressing:

1. This strategy isn't normally utilized.

2. In this strategy, the prestressing is finished by altering the external responses (by presenting diverse help conditions).

3. According to underneath, the just upheld bar is prestressed externally by jacks.

4. The externally prestressing framework requires particular precision in arranging and application.

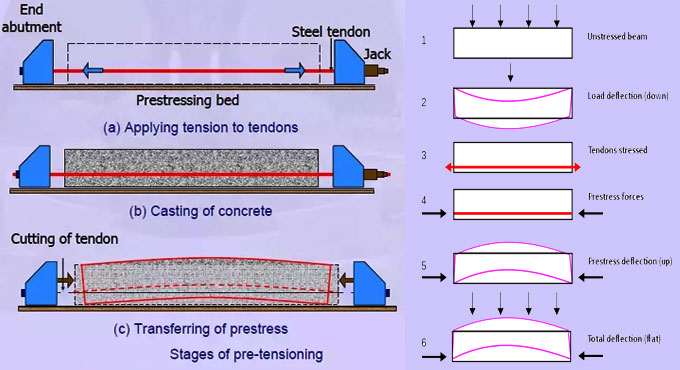

Pre-Tensioning: In Pre-tensioning, the steel tendons are tensioned before the concrete is cast. The tendons are briefly tied down against certain projections and afterward cut or discharged after the concrete has been set and solidified.

The prestressing power is moved to this concrete by the bond along the length of the tendon. Pre-tensioning is commonly done in precasting plants in changeless beds, which are utilized to create Pre-tensioned precast concrete components for the structure business.

Post-Tensioning

In Post-tensioning, the steel tendons are tensioned after the concrete has been cast and solidified. Post-tensioning is performed by two fundamental activities: tensioning the steel wires or strands by pressure driven jacks that stretch the strands while bearing against the finishes of the member and afterward supplanting the jacks by lasting safe havens that bear on the member and keep up the steel strands in tension.

A tendon is commonly made of wires, strands, or bars. Wires and strands can be tensioned in gatherings, while bars are tensioned each in turn. In the post-tensioning procedure, the steel tendons are set in the formwork before the concrete is cast, and the tendons are kept from attaching to the concrete by waterproof paper wrapping or a metal conduit (sheath).

Tendons bonded to the concrete are called bonded tendons. Unbonded tendons, left without grout or covered with oil, have no bond all through the length of the tendon.