Pile Load Test Procedure

The objective of performing pile driving test is to get clear ideas on the design bearing strength, soil condition, design length of pile, construction period and suitableness of construction equipment. A engineer should be present while conducting the pile driving test.

So, the Contractor should conduct the loading test for the pile prior to accomplishment of series of piling. The loading test procedure should be maintained with instructions provided by Engineer?s. If it is not mentioned in the designing document, in proportion to each diameter, length, bearing capacity of pile from the quantity of trial piles should be in excess of 1% of pile quantity and at least 2 piles.

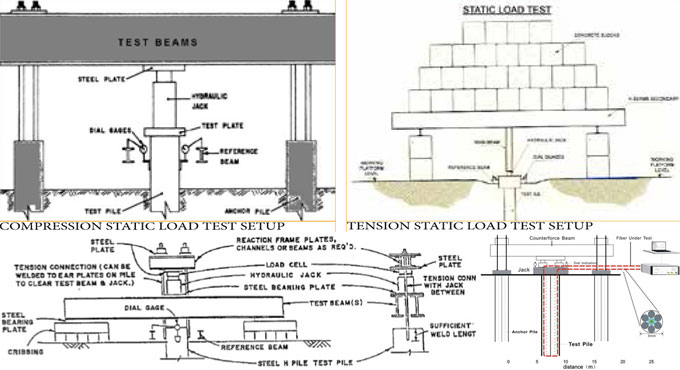

STATIC LOAD TEST: Prior to proceeding series of piling, the Contractor should conduct the static loading test for the pile. The Contractor must set up the pile static loading test thesis and present to the concerned engineer for confirmation prior to execution. The test should thoroughly abide by the sanctioned designing document.

Its content should point out the followings:

a. Characteristics s of construction

b. Characteristics of the ground at the constructing site and at the testing position

c. Proceeding method

d. Resting time of pile as soon as the until testing method is finished

e. Trial strength and greatest change of pile position as predicted.

f. Process for loading extending

g. Prediction on the time, progress of trial organizing.

h. Necessities on testing equipment

i. Other essential needs.

DYNAMIC LOAD TEST: Dynamic load testing should be carried out throughout pile driving work. Wave speed should be calculated for pile before arranging the pole for loading test.

While computing the wave speed, pile shall be placed horizontally on flat ground, and calculation is necessary so that pile can?t be meet with other piles. Pile shall be pushed down to the depth of attaining ultimate bearing capacity.

While pushing down the pile, the stress that operates on pile shall be supervised and managed to keep it under the permissible value. If required, striking energy transferred to pile shall be decreased to retain the stress under the permissible value with the inclusion of cushion or by minimizing the output hammer energy.

As soon as the dynamic loading test is finished, the Contractor should convey the report to the Engineer for verification and find out the number of pile and driving depth for the work.

When passed 24 hours from the execution of dynamic pile load testing, test instrument shall be affixed with the pile and pile should have been re-driven. Penetration depth of pile throughout re-driving should be under 150mm, and the number of hammering should be under 50 times.