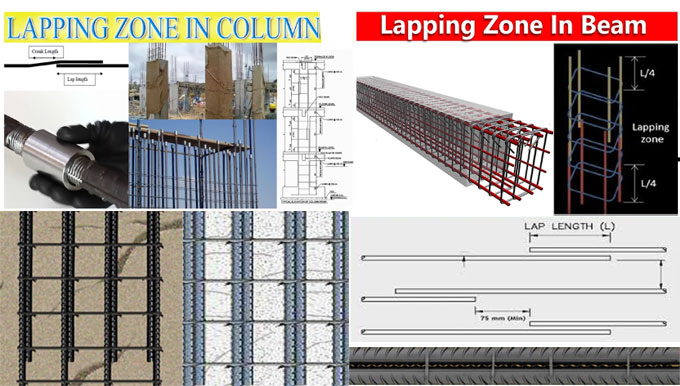

Minimum lapping length in column, beam, slab and wall

This civil engineering article provides some vital information on least lapping length in structure at the time of doing reinforcement work on the structure.

There are following types of members :-

Compression member ? Compression members belong to structural components which are driven jointly or bear a load, in technical term they are exposed to axial compressive forces. The columns, posts, vertical members and top chord of trusses are included here.

Tension member ? Tension members belong to structural components which are exposed to axial tensile forces. The beam, slab, horizontal members as well as bracing for buildings and bridges, truss members, cables in suspended roof systems etc. are included here.

In RCC walls, both members will operate as there are horizontal and vertical bars.

Least lapping length for compression member varies from 40d to 48d.

Least lapping length for tension member varies from 60d to 69d.

Here, d denotes dia of bar.

The lapping length is dependent on grade of concrete and grade of steel. If grade of concrete is increased, the lapping length will be reduced.

Why lapping length is provided ?

At the time of arranging steel in Reinforced concrete structure, if the desired length of single bar is short, the lapping of two bars is performed side by side.

Lapping is described as the overlapping of two bars side by side up to the design length. Normally, the stock length of steel bars is confined to 12m for smooth transmission of steel bars to the construction site. As for example, assume to construct a 100ft tall column. But it can?t be availed practically. So, the bars should be cut each second story.

After that, the tension forces should be shifted from one bar to the other bar at the position of disruption of the bar. Therefore, the second bar is retained narrowly to the first bar and overlapping is performed. This amount of overlapping among two bars is known as ?lap length?.

Lapping is normally provided where least bending stress exists. Normally, lap length is 50d i.e. 50 times the bar diameter, when both bars have equivalent diameter.

To get more details, go through the following video tutorial.

Video Source: Tutorials Tips