How to perform mix design based on IS Code 10262

You can define concrete mix design as the method of choosing the perfect components of concrete and finding out their proportional amounts (ratios of cement, sand and aggregates) to develop a concrete maintaining the necessary strength, stability, and workability as reasonably as possible.

The primary objective of concrete mix design is to retain the most perfect proportions of the basic materials to satisfy the requirements of the structure being constructed. Mix design fulfills the following purposes :-

a. To attain the designed/desired functionality in the plastic stage

b. To attain the desired least strength in the hardened stage

c. To attain the desired stability in the specified environmental conditions

d. To create concrete as cost-effectively as possible

The following point should be taken into consideration at the time of designing concrete mixes: Cost, Specification, Workability, Strength and durability.

Principles of mix design:

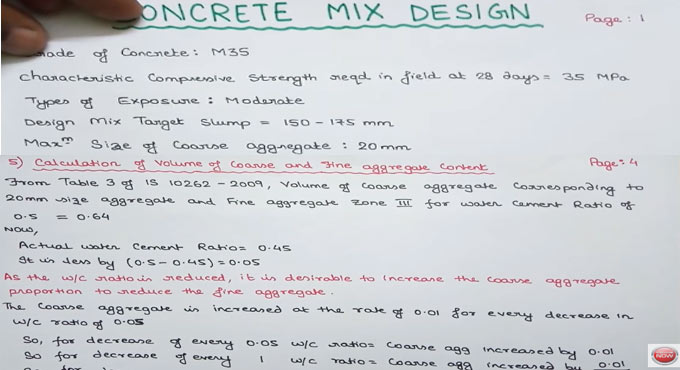

a. The grade of concrete and their characteristic strength?s and standard deviations

b. The type of cement

c. The types and sizes of aggregates and their sources supply

d. The nominal maximum sizes of aggregates

e. Maximum and minimum cement content in kg/m3

f. Proportion of water cement

g. The degree of workability of concrete on the basis of placing conditions

h. Air content along with entrained air

i. The maximum/minimum thickness of concrete

j. The maximum/minimum temperature of fresh concrete

k. Type of water accessible for mixing and curing

l. The source of water and the impurities existing in it

In this regard, an exclusive video tutorial is presented by the renowned engineer Mukesh Shaw. The video teaches you how to perform mix design of concrete following IS code 10262.

Video Source: L & T - Learning Technology