How to Calculate Quantity of Steel in One Way Slab

About One Way Slabs: A one way slab is supported on two opposite side only thus structural action is only in one direction. Total load is carried in the direction perpendicular to the supporting beam. If a slab is supported on all the four sides but the ratio of longer span (l) to shorten span (b) is greater than 2, then the slab will be considered as a one way slab.

Because due to the huge difference in lengths, load is not transferred to the shorter beams. Main reinforcement is provided in only one direction for one way slabs.

When the L/B ratio is equal to or greater than two, one way slab is provided. It is supported only on two opposite sides. Rigid supports hold the sides up. Also, it carries the load by flexure. The load is taken in a direction perpendicular to the support. Uniformly loaded one-way slab deforms into the cylindrical surface and hence bending moment develops only in one direction.

The main bars are provided in the shorter span In one-way slabs. While with the crank to counteract positive bending moment and distribution bars are provided in the longer span.

This is done for distributing the load and to prevent shrinkage cracks. For calculating the quantity of steel needed in one way slabs, in short, calculating one way slab bbs, let's take an example for better understanding.

Let?s suppose we have a one way slab plan with following data.

Length = 6 Meter

Width = 2 Meter

Main Bar = 12 diameter, Spacing ? 100 mm c/c

Distribution Bar = 10 mm, Spacing ? 125 mm c/c

Slab Thickness = 150 mm

Clear Cover = 25 mm

Development Length Ld = 40d

First step: Calculating the number of bars

In the beginning we will calculate the numbers of Main bar and Distribution bar that are required.

Numbers of Bars = Total length/ spacing of bar + 1

So, Numbers of main bars = 6000/100 +1

= 61 numbers

And, Numbers of Distribution bars = 2000/125 +1

= 17 Numbers

Second Step: Calculating the Cutting Length

Now we will calculate the cutting lengths of main bars and distribution bars.

For Main Bar - Cutting Length = Length + 2 x Ld + (1 x 0.42D) ? 2 x 1d

Where

L = Clear Span of Slab

Ld = Development Length (Take = 40d where d is diameter of bar)

0.42D = Crank or Inclined length of bar

1d = For 45 bend

Calculation of inclined Length D

D = Slab Thickness ? Clear cover (top and bottom) ? Diameter of Bar

D = 150 ? 2 x 25 ? 12

D = 88 mm

Cutting Length of Main Bar

= 2000 + (2 x 40 x 12) + (0.42 x 88) ? 1 x 12

= 2984.96 mm say 2985 mm or 2.985 meter

Cutting length of distribution Bar

= Clear Span (Longer Span) + 2 Ld

= 6000 + ( 2 x 40 x 10 )

= 6800 mm or 6.8 meter

Third Step: Calculating the Steel Weight

Now we have to calculate the weight of steel required in the slab, since this will go into cost estimation.

Weight of Main Bar

= Numbers of bar x Cutting Length x Unit Weight of Bar (12 mm = 0.888)

= 61 x 2.985 x 0.888

= 161.69 kg

Weight of Distribution Bar

= Numbers of bar x Cutting Length x Unit Weight of Bar (10 mm = 0.0.617)

= 17 x 6.8 x 0.62

= 71.672 kg

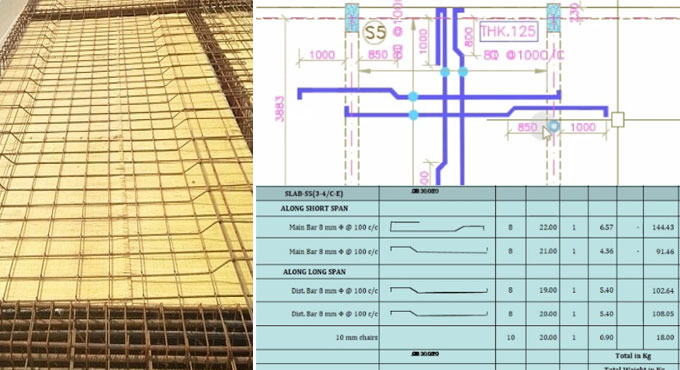

BBS of One Way Slab

Main bar (12mm) - 2.985 meters, 61 pieces, total 182.085 meters of bar weighing 161.69 kgs.

Distribution bar (10mm) - 6.8 meters, 17 pieces, total 115.6 meters of bar weighing 71.672 kgs.

We hope that the above method of calculating steel quantity in one-way slabs was useful to you. Please let us know what you think! Also, we would love to hear about your suggestions and ideas.