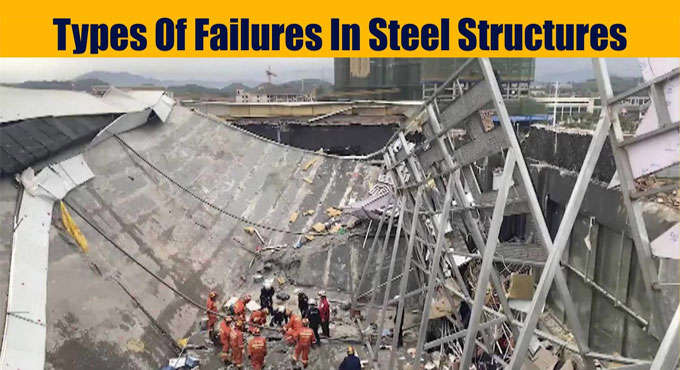

Types of Failures in Steel Structures

Steel is one of the famous construction materials close to concrete in the construction business. The high strength and flexibility are the essential properties of steel that make its place in practically all the renowned high rises far and wide.

Steel structures are created by singular steel individuals, welded or darted together to get a last unit. The slim individuals and joints are the basic focuses on a steel structure that must be intended for basic worries with most extreme consideration. Any variety or error can bring about auxiliary failures of the steel structure, which changes with the sort of burden acting and the kind of structure.

The article clarifies the basic failure methods of steel structures.

Sorts of Failures in Steel Structures - The significant sorts of failures saw in a steel structure are:

1. Compression Failure

2. Tension Failure

3. Flexure Failure

4. Shear Failure

1. Compression Failure in Steel Structures: While considering a steel structure, the individuals that are exposed to compression are columns and supports. At the point when the compression load following up on the pivot of the part is high (higher than the heap for which it was structured), it brings about compression failure or clasping of the part.

The plan of the column structure includes the assurance of a parameter called the thinness proportion. The slimness proportion is characterized as the proportion of the cross-sectional zone of the basic component to the length of the part.

This parameter impacts locking in structures?higher the thinness proportion of the allowed part more to clasp.

2. Tension Failure in Steel Structures: The elastic pressure failure is seen in part under tension burden. Support individuals or holders of the steel structure are exposed to tension failure. The elastic burden following up on the part pulls the part past its material strength, which brings about the ductile failure of the part.

Tension failure in steel auxiliary components happens in various stages. The wonder begins with the necking of the material cross-area and, at long last, material failure.

Necking is the decrease of cross-sectional zone under ductile burden. The failure happens when the material area arrives at the least cross-segment.

3. Flexural Failure in Steel Structures: Flexural failures happen in flexural individuals like pillars and supports. The flexural individuals, when exposed to a significant level of flexural loadings, curve, or causes clasping. Because of the high strength of steel, they are intended to be thin and productive. This can bring about clasping or twisting of the part. Substantial and thick flexural individuals are less defenseless to flexural failure.

Flexural individuals are exposed to flexural loads that make compression and tension powers in the part. It isn't generally conceivable to expect the stacking activity in the focal point of the flexural part.

Along these lines, a capriciousness in stacking is likely that would bomb the compression rib of the steel shaft. The unconventionality would make a turning second to the shaft spine, and the pillar begins to move laterally. This is called lateral-torsional clasping.

Lateral limitations are given to forestall locking in steel structures due to flexural loadings. The flexural strength is a lot of subject to the material strength. The part experiences failure if the flexural stacking is more noteworthy than the material strength.

Column is a compression part that experiences comparable failure when it is exposed to twisting burdens.

4. Shear Failure of Steel Structures: Steel structure is a mix of associations, i.e., part to column association, part to support association, and so on. Shear failure noticeably happens in these association territories. Every association in a steel structure has its shear pressure esteem.

On the off chance that the worth isn't considered accurately during the plan of association, failure happens. Steel structures are made either by blasted association or welded association or a blend of both.