Different methods to verify the quality of fresh concrete

The followings tests are conducted for quality checking of fresh concrete :-

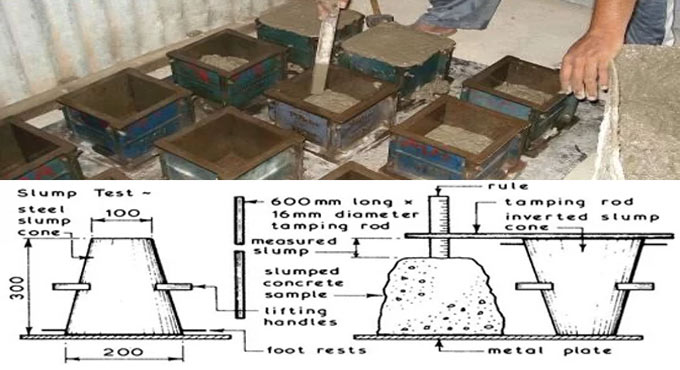

a. Slump Test (ASTM C 143)

b. Temperature Test (ASTM C 106)

c. Air Content Test (ASTM C 173)

d. Compressive Test (ASTM C 31)

SLUMP TEST: This test is conducted to evaluate the stability and workability of fresh concrete. Various types of equipments like slump cone, base plate, steel rod, scoop, funnel, brush etc. are required for this test.

Process :-

a. The slump cone should be filled in three layers

b. Provide 25 blows to every layers

c. Level the top surface

d. Eliminate the slump cone uprightly within 3 to 5 seconds

e. Calculate the collapsed height in mm from top

TEMPERATURE TEST: This test should be conducted to find out the temperature of fresh concrete at construction site.

A thermometer (manual or digital) is required for this test and the perfectness should be ? 0.5 C degree

Process:

a. Enter the thermometer in fresh concrete sample at a depth of minimum 75 mm.

b. Leave the thermometer in fresh concrete for 2 minutes.

c. Obtain the reading with perfectness of 0.5 C degree.

AIR CONTENT TEST: This test is suitable to find out the proportion of air content in fresh concrete.

Different types of equipments like air meter, flask, 16 mm rod, straightedge, water bowel etc. are required for this test.

Process :-

a. The air meter bowel should be filled in three layers from fresh concrete.

b. Provide 25 blows to every layers.

c. Level the top surface.

d. Provide the cover and fine-ture the air gage to zero.

e. Fill the voids with water.

f. Open the valve of air meter and calculate the water content.

Compressive Strength Test: This test is mainly conducted to find out the compressive strength of fresh concrete after it gets solidified in 7, 28 and 90 days. Different types of equipments like cylinders, 16 mm rod, straightedge, scoop, funnel, base plate etc. are required for this test.

Process :-

a. Grease the inside of cylinder with oil.

b. The cylinders should be filled in three layers from fresh concrete.

c. Provide 25 blows to every layers.

d. Level the top surface.

e. Apply vapour barrier to wrap the surface.

f. Eliminate the vapour barrier after 24 hours and arrange the cylinders in moisture room.