Industrial Roof Trusses: Understanding and Designing

The industrial buildings such as godowns and factory floors are often low rise structures with few or none internal walls. In such buildings, special Care needs to be taken while designing industrial roof trusses, since large spans need to support the entire roofing system without intermittent support. Trusses with roof covering materials make up of the entire roofing assembly here.

What are Trusses?

Trusses are triangular formation of metal sections, usually used to span large lengths in space instead of solid girders. The external load apply mostly axial forces on the members in a truss. Depending upon how the force is applied, trusses can be designed in the following two ways:

Plane Trusses: where the external load is placed on the plane of the truss.

Space Trusses: where the external load can be applied to any three-dimensional space within.

How are Trusses Built?

Trusses mostly consist of axially loaded members to support loads. The reason for this that when steel members are subjected to axial forces, they perform better in bearing that load, than members that are in flexure. This is because the cross-section of such a system is uniformly stressed under axial forces.

Trusses are very common in most architecture. Mostly used to span long distances, they are well suited to bear the load of single-storey industrial buildings.

They can also be designed to bear gravity loads in long span floors. For the same reason they are also mounted to bear loads of long span bridges.

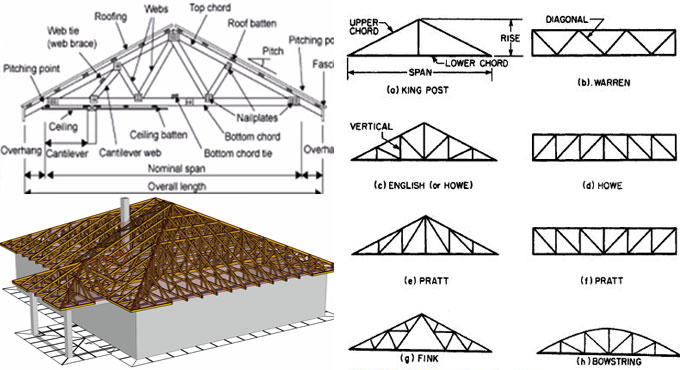

What are the Components in a Roof Truss?

In industrial roof truss, we see the following parts forming the trusses.

1. Principal Rafter: The top chord member of the truss. Depending upon whether the purlins are supported at the nodes or are intermediate of nodes, the principal rafters is subjected to compressive force or bending moment.

2. Principal Tie: It is the lower chord member in a truss. The gravity load applies tension to it.

3. Strut: The members in a truss which are subjected to compressive force are called struts (except the rafter and tie).

4. Sling: The members in a truss which are subjected to tensile force are called slings.

5. Purlin: The members that carry the roof (and corresponding) weight directly and channel it to the other members are called purlins.

6. Bracing: These are placed in case the truss is subjected to accidental unforeseen forces such as lateral pressure.

Types of Industrial Roof Trusses:

There are several types of industrial roof trusses, depending upon how the span is made, quality of elegance, and demands of the building particular and venting systems. These can vary a lot. There are Six main types of roof trusses as listed below.

1. Pratt Truss

2. Howe Truss

3. Fink Truss

4. Fan Truss

5. Fink-Fan Truss

6. Mansard Truss

For further details on how the loads are calculated on a truss and other design details, please read this.