How to estimate concrete mix design for M15 Grade

Mix design stands for a method that can be applied for choosing appropriate components as well as ascertaining their pertinent ratios with the purpose of maintaining definite minimum workability, strength and stability as inexpensively as possible of concrete.

M10 M15 M20 etc. belong to all grades of concrete following the Indian Standard. The 'M' stands for 'Mix' accompanied by a number demonstrating the compressive strength of that mix in N/mm^2. A mix denotes a particular ratio in which cement, fine(sand) and coarse aggregate(gravel) are blended. In M15, 15 N/mm2 refers to the characteristic compressive strength of concrete cube at 28 days.

Types of Mixes:

1. Nominal Mixes: Earlier the specifications for concrete set the ratios of cement, fine and coarse aggregates. These mixes of fixed cement-aggregate ratio make sure that sufficient strength is maintained that is called nominal mixes. Because of the inconstancy of mix ingredients the nominal concrete for a specified workability greatly differ in strength.

2. Standard mixes: The nominal mixes of fixed cement-aggregate ratio (by volume) differ largely in strength and lead to under- or over-rich mixes. Due to this, the least compressive strength is contained in various specifications. These mixes are known as standard mixes.

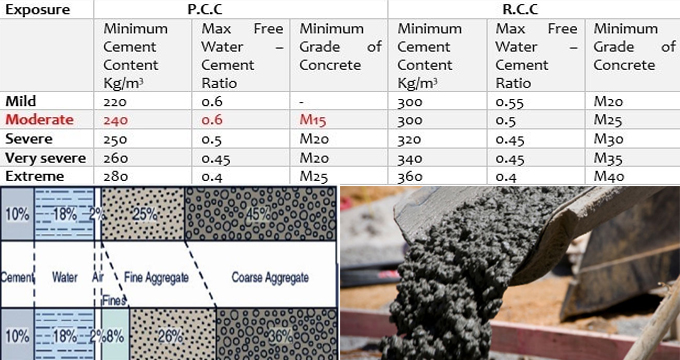

IS 456-2000 has assigned the concrete mixes into a number of grades as M10, M15, M20, M25, M30, M35 and M40. Here, M stands for the mix and the number to the indicated 28 day cube strength of mix in N/mm2. The mixes of grades M10, M15, M20 and M25 relate approximately to the mix ratios (1:3:6), (1:2:4), (1:1.5:3) and (1:1:2) correspondingly.

3. Designed Mixes: In these mixes the performance of the concrete is indicated by the designer but the mix ratios are obtained by the producer of concrete, apart from the minimum cement content is put aside. It is the most authentic method for choosing the mix ratios with particular materials. With this method, the concrete can be produced cost-effectively maintaining the appropriate properties. The designed mix can?t provide the exact mix proportions for the prescribed performance.

Go through the following exclusive article to gather more information on concrete mix design calculation for M15 grade. theconstructor.org