Calculation of Concrete Blocks and its various types used in civil projects

History of Concrete Blocks: Though history records the use of concrete blocks by the Romans, Greeks and even Egyptians (some of the two-tonne blocks that make up the Pyramids are believed to be a primitive form of concrete), modern-type blocks were first cast, albeit in modest quantities, in around the middle of the nineteenth century. In 1827, Joseph Aspidin devised the basic mix that we would still recognise today. The mix, cast in wooden moulds, consisted of powdered limestone and clay mixed with water.

Today, the immense versatility of concrete blocks is demonstrated in their use throughout a building from its foundation walls, through cavity walls, monolithic walls, partition walls, separating walls and as a component of ?beam and block? flooring. Concrete blocks? advantageous properties are reflected in their myriad of variations of strength, insulating and sound-reducing properties.

Types of Concrete Block

There are mainly three types of Concrete Block:

1. Dense aggregate block

2. Lightweight aggregate block

3. Aerated concrete or ?aircrete? block

Dense aggregate block

The blocks are made of Portland cement, natural aggregate or blastfurnace slag. The usual mix is 1 part of cement to 6 or 8 of aggregate by volume. These blocks are as heavy per cubic metre as bricks, they are not good thermal insulators and their strength in resisting crushing is less than that of most well burned bricks. These blocks are used for internal and external loadbearing walls, including walls below ground.

Lightweight aggregate block

The lightweight aggregate is a kind of coarse aggregate which is used in the production of lightweight concrete products like concrete block, structural concrete, and pavement. The shape of the lightweight aggregate used in concrete can be cubical, rounded, angular, or of any other shape. The shape and texture can directly affect its workability.

Aerated concrete or ?aircrete? block

The blocks are made from cement, lime, sand, pulverised fuel ash (PFA) and water. PFA is mixed with sand and water to form a slurry. This is then heated before being mixed with cement, lime and a small amount of aluminium sulphate powder.

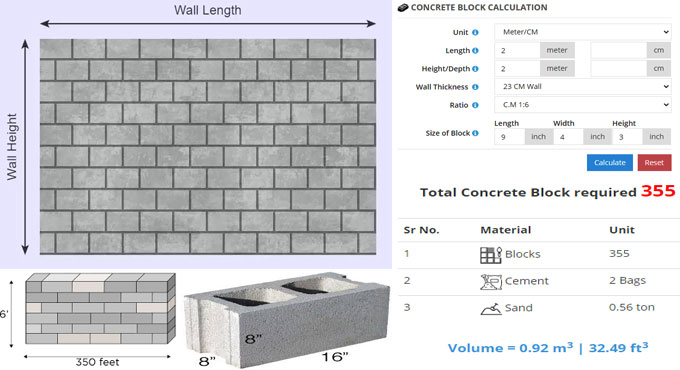

Calculation of Concrete Blocks

Calculating the quantity of blocks needed for a building is a straightforward process that does not require any previous building or architectural skills. Here, we will demonstrate easy step by step process to calculate the concrete blocks used for civil construction.

Step 1

Volume of Concrete Block

= Length (m) X Depth (m) X Wall thickness (m)

= 2 X 2 X 0.23

= 0.92m3

= 32.49 ft3.

Block Size

= 9 inch X 4 inch X 3 inch

= (9 X 0.0254) X (4 X 0.0254) X (3 X0.02454)

= 0.2286 (m) X 0.1016 (m) X 0.0762 (m)

Size of the block with Mortar

= (0.2286 + 0.015) X (0.1016+ 0.015) X (0.0762 + 0.015)

Size of the block with Mortar

= 0.2436 (m) X 0.1166 (m) X 0.0912 (m)

No of Blocks = Volume of one concrete block / Volume of one block

=0.9200 m3 /0.2436 X 0.1166 X 0.0912

No of Blocks = 355 Blocks

Actual Volume of Blocks Morter = No of Blocks X Volume of Block Without Morter

= 355 ? (0.2286 ? 0.1016 ? 0.0762)

= 355 ? 0.0018

= 0.6286 m3

Quantity of Mortar =Volume of Block Masonry - Actual Volume of Blocks without mortar

Quantity of Mortar

= 0.9200 - 0.6286

= 0.2914 m3

Add 15% more for wastage, Non - uniform thickness of mortar joins

Quantity of Mortar

= 0.2914 + (0.2914 X 15/100)

= 0.3352

Add 25% more for Dry Volume

Quantity of Mortar

= 0.3352 + (0.3352 X 25/100)

= 0.4190 m3

Step 2

Amount of Cement = Cement /sum of ratio X Quantity of Morter

Cement

= 1/7 X 0.4190

= 0.0599m3

1 Bag of Cement = 0.035 m3

No of Cement Bags = 0.0599/0.035

No of Cement bags = 86 kgs

Step 3

Amount of Sand Required

= Sand /Sum of Ratio X Quantity of Morter

Sand = 6/7 X 0.4190

= 0.3591 m3

By Considering dry loose bulk density of sand 1550 kg/m3

Sand = 556.61 kg

Importance of Concrete Block

A concrete block is a blend of grated cement, sand, gravel and water. When all of these components are assorted tighter, they form a light grey block with a refined surface pattern possessing highly impressive strength. An elementary concrete block will go on to make the structures more energy-efficient and permanent.

You can calculate online Concrete Block Calculator. Click here: civil-engineering-calculators.com