Causes and remedies of leakage in Jack Arch Roof

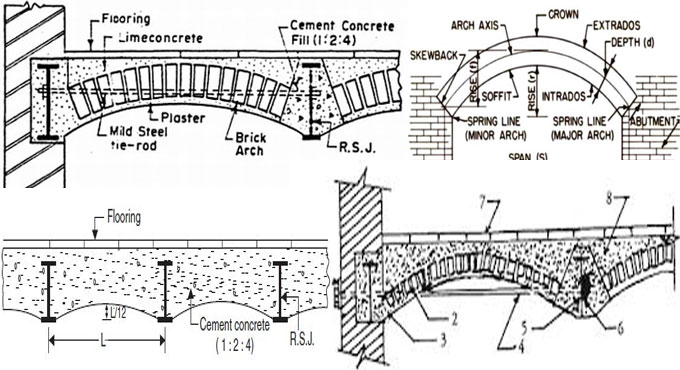

Jack arch Roof construction is mostly found in brick or concrete. It?s arch is constructed with either brick or concrete. The support for the arch is provided on the lower flange of mild steel joists (RSJs). By applying rolled steel joists, support is provided at their ends on the walls or on the longitudinal girders. They are positioned at a gapping of 1m to 1.5m centre to centre.

The rise of the arch remains identical to 1/12th of the span. To flatten the roof, layer of concrete is then poured over the roof. The layer thickness of concrete over the crown of the arch should not be under 15cm.

The tension forms at the ends of the arch due to the super-imposed load on the arch. At the ends of an arch, there are steel tie rods having a proper spacing of 1.8m to 2.4m.

Given below, the reasons for leakages in a Jack Arch Roof and solutions to resolve the issue.

The two main reasons for leakage are:

1. substandard quality of cement

2. improper grade of sand

Repair of the roof: Proper solution should be provide to stop the Jack Arch roof leakage to stay away from frequent water leakage problem in near future. It can be done by waterproofing the roof.

Given below, some useful tips for repairing and waterproofing the Jack Arch Roof:

Step one: The old cement mortar and tiles should be eliminated in order to arrange the new cement mortar make it rigid over the rough roof surface.

Step two: Once the cement mortar is scoured, fresh cement mortar is placed and discarded to dry.

Step three: Once the drying of cement mortar is completed, waterproofing is performed so that the leakage does not occur further. Waterproofing material is blended in a drum of water and splatter over the cement mortar layer. But ensure that the waterproofing material spreads over every corner of the roof.

Step four: As soon as the waterproofing is completed, tiling is performed through a suitable adhesive.