How to Prepare A Bill of Quantities in 6 Easy Steps

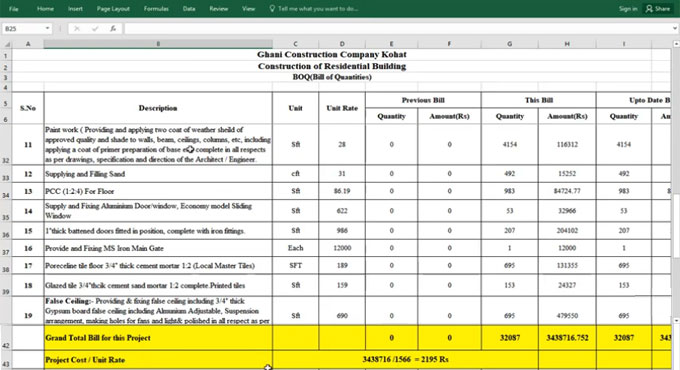

When you begin the planning of a construction project, you are faced with the inevitable question: how much will it cost? The answer to that can be found in a Bill of Quantities, or BoQ in short. Today, we will talk about how to prepare a bill of quantities, in 6 easy steps.

A Bill of Quantities (BoQ) lists the total materials required to complete the architect's design for a construction project, such as a house or other structure. BoQs are typically prepared by a quantity surveyor or civil engineer who has expertise at estimating the materials required for a project.

The bill of quantity enables you to get quotes for the project that are as accurate as possible. Even if you don't prepare the BoQ yourself, it's still worth knowing how a bill of quantity should be prepared, so you can evaluate the quality of the finished product.

The following are the steps you can follow to properly set up a bill of quantity.

1. Set up the spreadsheet

Open a new file in your favourite spreadsheet program, online or offline. (We recommend using LibreOffice, one of the best free office software ever.) Now set up the column as follows:

- Item numbers

- Description

- Unit of measurement

- Quantity

- Rate for the item

- Labor cost

- Total cost

As expected, your item numbers should start from 1, and reiterate as you change through the categories or sections of the build. The data for the rates and labor costs should be filled in by respective contractors, or, as per the quotes you got from them.

2. Prepare list of materials

You need to input all the materials you will need to complete the project, and I do mean, all. It?s better if you make the full list before typing it into the spreadsheet. You will need to scan the architectural plans and talk to the engineers to find out exactly what you will need. Your list will include not only building materials like bricks, cement, sand etc., but also electrical and plumbing material as well as they go into the ceilings and walls.

The second job here is to identify the unit of measurement for each material and denote it clearly. Errors in this can mess up a lot of things ? it is quite a bit of nasty shock to realize that a cubic meter of sand is not remotely close to a cubic foot of it. Dot your i?s and cross your t?s for all the gallons vs liters, inch vs cm, kgs vs lbs.

Once you got the items list and their quantity down pat in your notebook, fill them out in your BoQ spreadsheet. Put each item beside its item number and follow it by its quantity that is required for the project completion. You should also add 15% to the total quantity, to allow wastages.

3. Categorize the project specifics

Break down the project into specific sections or categories. Since different parts of your project will likely be handled by different contractors or subcontractors, split up your list of materials into those sections. This action is very important, since it is required for each contractor or subcontractor as well as the client to know how much each of their work for the project will cost.

The names for these sections should depend upon each phase of work that needs to be done in the project. For example, for a standard house, the sections may be the following:

- RCC Frame

- Plumbing

- Electrical

- Kitchen

- Bath

- Flooring

Try to follow the actual steps of construction in this categorization process, to reduce headache.

4. Labor cost estimation

Figure out the labor wages required to complete each segment. You can do this by estimating the man-hours required to finish each task, and you can find that out by asking experienced labor contractors. This estimation should be kept close to the chest since not all labors are experienced or capable the same way.

As you talk to contractors, do employ a quantity surveyor to figure out these parts for you as well. An experienced quantity surveyor would usually be able to estimate this off the top of their head.

5. Draft a schedule

Since you now have the data about how much time it will take to complete each segment of the project, and you know the order in which they should be executed, you can build up a work schedule based on the available data in the bill of quantity. Make space in the schedule for unforeseen circumstances.

For example, if you've estimated it will take 1,000 man-hours to build your house, assuming the contractors work 40 hours a week and there are no delays, it would take them 25 weeks to complete your house. However, to allow for delays, you're better off planning for it to take 30 to 40 weeks.

6. Get contractor estimates

Ask the contractors about the costs that would be incurred based on the data in the BoQ. Get at least 3 different estimates on your project, to figure out the shortfalls with each estimate and get the best offer. Give the contractors a basic idea about their tasks for the project to see if they can get it done in the time prescribed.

If they are interested, send them your BoQ separately to each, and they will enter their estimates in each field corresponding to materials and tasks. When you receive the files from each contractor, you can compare them yourself.

To get more details, go through the following video tutorial.

Video Source: Civil Study