Beams used in Construction: H-Beam vs I-Beam

Why are Beams used in Construction?

Beams are horizontal structural elements used in construction to support loads and transfer them to vertical supports, such as columns or walls. They are typically made of steel, wood, or reinforced concrete, and can be of various shapes and sizes, depending on the specific requirements of the structure.

In simple terms, beams are like long, narrow tables that support the weight of a building or structure. They are often used to span openings, such as doorways and windows, and to support floors, roofs, and ceilings. Beams can also be used to create cantilevers, structures extending beyond their supporting columns or walls.

The design of a beam depends on several factors, such as the load it needs to support, the span length, and the material type used. Engineers use complex mathematical calculations and computer simulations to determine the optimal size, shape, and placement of beams in a building or structure.

What is H-Beam in Construction?

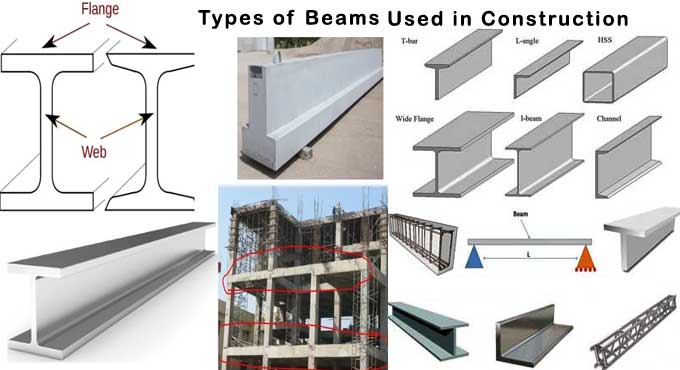

H-beams, also known as I-beams, are structural steel beams with an "H" cross-section. They are widely used in the construction industry as they provide excellent support and stability in various building projects.

The H-beam is named after its distinctive shape, which resembles the letter "H." The horizontal elements of the beam are called flanges, and the vertical element is called the web. The flanges are wider than the web, which gives the H-beam its characteristic shape.

H-beams are commonly used in the construction of buildings, bridges, and other structures that require support beams. They can also be used as columns or as part of a truss system. The wide flange design makes them ideal for carrying heavy loads and resisting bending, making them a popular choice for construction projects where strength is critical.

What is I-Beam in Construction?

An I-beam, also known as a W-beam, is a type of steel beam with a cross-section resembling the shape of the letter "I". I-beams are commonly used in construction to support heavy loads over long spans.

The I-beam is composed of two horizontal elements, called flanges, and a vertical element called the web. The flanges are typically wider than the web, which helps to distribute weight evenly and resist bending. The I-beam's design allows it to carry heavy loads while maintaining a relatively lightweight, making it a popular choice for construction projects.

I-beams can be used in a variety of construction applications, including as load-bearing beams in buildings and bridges, as well as in the construction of cranes, machinery, and other heavy equipment. They are available in a range of sizes and strengths, making them suitable for different types of construction projects.

What are the major differences between H-Beam and I-Beam?

The major differences between H-beams and I-beams lie in their cross-sectional shape and the distribution of weight along the beam. Here are some key differences between H-beams and I-beams:

- Cross-Sectional Shape: H-beams have a wider flange than I-beams, giving them an "H" shape when viewed from the end. I-beams have a narrower flange than H-beams, giving them an "I" shape when viewed from the end.

- Weight Distribution: The wider flanges of H-beams allow for greater weight distribution and stability, making them a better choice for heavy-duty applications. I-beams, on the other hand, distribute weight more evenly along the length of the beam, making them a more efficient choice for spanning long distances.

- Strength-to-Weight Ratio: H-beams are generally heavier and have a higher strength-to-weight ratio than I-beams, making them a better choice for applications where strength is critical. I-beams are lighter and have a lower strength-to-weight ratio, making them a better choice for applications where weight is a concern.

- Availability: H-beams are more commonly available in larger sizes and lengths than I-beams, making them a better choice for larger construction projects.

- Cost: The cost of H-beams is generally higher than I-beams due to their greater size and weight.

- Design Flexibility: H-beams offer more design flexibility than I-beams because of their wider flange, which allows for greater architectural freedom.

- Installation: H-beams are often more difficult to install than I-beams due to their weight and size. Special equipment and expertise may be required to install H-beams properly.

- Applications: H-beams are commonly used in heavy-duty construction projects, such as skyscrapers, bridges, and large industrial buildings. I-beams are used in a variety of applications, including residential construction, commercial buildings, and smaller industrial projects.

- Material: H-beams and I-beams can be made from a variety of materials, including carbon steel, stainless steel, and aluminium. The material chosen depends on the specific application and the desired strength-to-weight ratio.

To get more details, watch the following video tutorial.

Video Source: Civil Work

It is important to note that H-beams and I-beams differ in terms of cost, design flexibility, installation, applications, and material. A construction project's specific needs, such as weight distribution, span, and load-bearing capacity, determine the choice between the two.