The concrete mix design and it?s requirement

Concrete mix design stands for the method of choosing proper materials of concrete as well as finding out their relevant amounts with the purpose of forming a concrete having necessary strength, longevity, and workability as cost-effectively as possible.

The mix design of concrete is impacted with the following factors :-

1. Compressive strength: It is one of the most vital characteristics of concrete and affects several definable properties of the hardened concrete. The mean compressive strength that is necessary at a particular time, usually 28 days, is liable for finding out the nominal water-cement ratio of the mix. The degree of compaction is the other factor that impacts the strength of concrete at a specified time and cured at a set temperature. Abraham?s law states that the strength of fully compacted concrete is conversely proportional to the water-cement ratio.

2. Functionality: The essential degree of functionality is based on the three factors which range from the size of the section being built up, the amount of reinforcement, and the applicable method of compaction. For the narrow and complex part with several corners or unapproachable parts, the concrete should contain an extreme functionality to attain full compaction with a proper amount of effort. It is also applicable to the embedded steel sections. The required functionality is based on the compacting equipment that exists at the site.

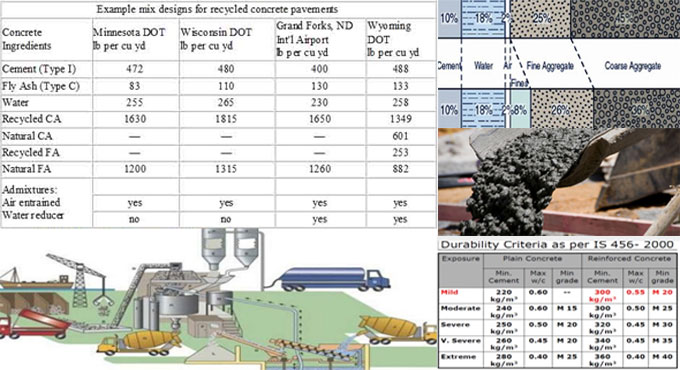

3. Longevity: The longevity of concrete is mainly dependent on how it can withstand the severe ecological conditions. High strength concrete lasts long as compared to low strength concrete. Under the conditions, when the high strength is unessential but high strength is necessary, the applicable water-cement ratio is dependent on the durability requirement.

4. Maximum nominal size of aggregate: Usually, if the size of aggregate is bigger, less amount of cement will be required for a specific water-cement ratio, as the functionality of concrete raises with increase in maximum size of the aggregate. But, the compressive strength is likely to be raised with the decrease in size of aggregate.

As per IS 456:2000 and IS 1343:1980 standard, it is stated that the nominal size of the aggregate should have been as large as possible.

5. Grading and type of aggregate: The grading of aggregate is affected by the mix proportions for a stipulated functionality and water-cement ratio. Coarser the grading leaner will be mix which can be used. Very lean mix is recommended because it does not include sufficient finer material to build the concrete cohesive.

The type of aggregate significantly affects the aggregate-cement ratio for the required functionality and specified water cement ratio. A crucial feature of a satisfactory aggregate is the consistency of the grading that is attainable by amalgamating various size fractions.

6. Quality Control: The degree of control is calculated statistically with the differences in test results. The difference in strength happens due to the differences in the properties of the mix ingredients and not managing perfectness in batching, mixing, placing, curing and testing. As the variation among the mean and minimum strengths of the mix is reduced, the cement-content required will also be decreased. The factor that manages this variation is defined as quality control.

For more information, go through the following article www.engineeringcivil.com