Details of laping length of steel bar in Reinforced Cement Concrete

In case the smaller dia bar is overlapped with the larger dia bar, lap length alias development length will be measured on the basis of the diameter of smaller dia bar.

As for instance, select a continuous beam having two members. There is a longitudinal bar with 25 dia for the first member, and a longitudinal bar with 16 dia for the second member. Now, at the time of lapping, the 25 dia bar is assigned with the second member and expanded upto the length ?Ld?that is estimated maintaining the diameter as 16mm. When the beam is designed as 16 dia, it is not necessary to expand 25 dia bar.

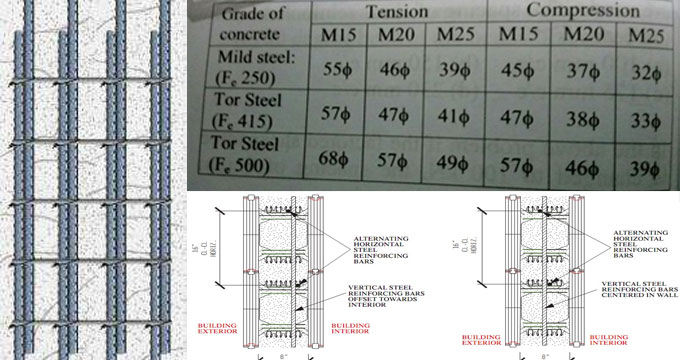

Given below, some ?Ld? value for quick reference :

I. Lap length of bars in bending tension should not be below ?Ld? or 30d

2. Lap length of bars in direct tension (water tanks) should not be below 2Ld or 30d

3. Lap length of bars in compression should not be under Ld or 24d

As per IS456:2000 standard for plain and reinforced concrete, the following is defined :-

When various types of bars are required to be spliced, the lap length is estimated based on the diameter of smaller bar.

How to compute lap length?

For bar that contains dia over 36mm, welding is essential. If welding is not done, then spiral of 6mm bar should arranged at lap.

Lap length along with anchorage value of hooks for bars in flexural tension must be larger of these two.

Development length (based on the eqn provided in IS 456, section 26.2.1)

30*dia of bar

For direct tension lap length will exceed of these two

2*development length

30*dia of bar

Some other crucial factors should be taken into consideration like cover, it can be verified in IS 456.

Article Source : http://onlinecivilforum.com