Importance of Cost Escalation

Cost Escalation or increment is a change that happens for specific goods or services in a set economy over a period and it is just like the concepts of increment and reduction except that escalation is specific and not very much driven by changes in the money supply but less sustained.

Generally escalation has general expansion related to money supply and sometimes happened by the changes in technology, practices and supply-demand unbalances which are specific for a good or service in a set economy. This escalation is calculated by examining the changes in price index calculates for any good or service; in future the escalation can be done with the help of econometrics. But escalation is not easy to measure with surveys as it generally occur in a micro-market and difficult to find.

The cost escalation left a big effect on a company?s competition and profits like it may affect the launch of a new project or either can decrease the productivity than before. In simple words, cost escalation in the supply chain for a previous product drives a constructor to both raise costs and lose rival advantage or to decrease the profit margin to keep up the price levels.

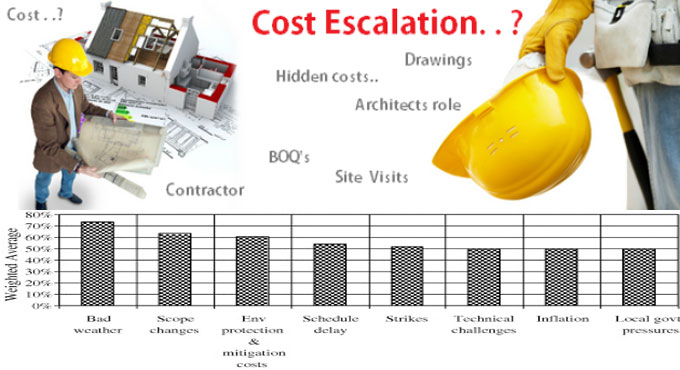

Here in below some points are discussed that might be responsible for the cost escalation for any product or company:

? Management: A low cost management is the basic reason of cost escalation or increment. Generally cost estimates causes for incomplete or wrong information that lead to cost escalation in a project or production run. Companies face this cost escalation when they don?t figure out the remain in line with original estimates and this cost escalation can affect a contract and suppliers sometime leave the companies for unforeseen cost increases in the period of a contract.

? Materials: Raw materials are the one of the main ingredients in a construction project and the ups or downs in the cost of the materials affect the budget of a project. When the change happens in the cost of these materials, that causes the cost escalation; the costs raise either the shortage of supplies, extreme demand for the materials or the lack of choices. Natural disasters or change in the climate can make a shortage of the supply of the materials? besides that, sometime growing economics affects the cost materials while some costly materials have no alternatives.

? Labor: Labors are the main workers in the project and the costs for them have left a strong impact on building costs that can be shown in companies where production method is labor concentrated. When the wages rise or employee benefits increase or additional training costs and the size of the workforce increase, it can lead the cost escalation. Not only this, the lower productivity or constant fall in the productivity happens but the labor costs remain same, it surely causes the cost escalation.

? Compliance: If the industry rules make deference than compliance, it causes the cost escalation; such as in manufacturing deference with health and safety regulations raises labor costs but deference with consumer laws can make changes in product design or quality control increases the manufacturing costs.

? Supply chain: Supply chains are the main sources of the raw materials which keep alive a project and make it complete but if any such changes happen in the sources of the supplies, that may leads cost escalation.

In addition to the above reasons, there are two more escalation clauses that are increasing the supply costs of the vendor and annual price. Some products, those have unstable prices used to make other goods, the prices of final goods have some instability in the price. If the buyers and sellers accept this escalation clause, the vendor will justify a price increase by showing the method of growing costs. Sometime, in an annual price adjustment escalation clause both the buyer and seller agree to a fixed price increment each year.

Article Souce: bizfluent.com