Fundamental Construction Method of RCC Column

RCC is the acronym of Reinforced Cement Concrete which is known as structural member of RCC frame structured building. Generally it is a vertical member that transmits load from slab and beam right away posterior soil.

We all know that column is the main backbone of a building. If any kind of column failure happens then the entire building collapses. Basically this failure takes place not because of the design fault; actually it happens owing to the inferior construction practice. That is why it is mandatory to have the proper knowledge of the construction method of RCC column.

RCC column construction process comprises of the four steps that are described below briefly:

1. Column layout work: This is the very first step of the RCC column construction method. The placements of columns are considered substantially in the worksite. It is performed by laying rope in accordance with grids as shown in the drawing and finally note the location of columns with respect to rope.

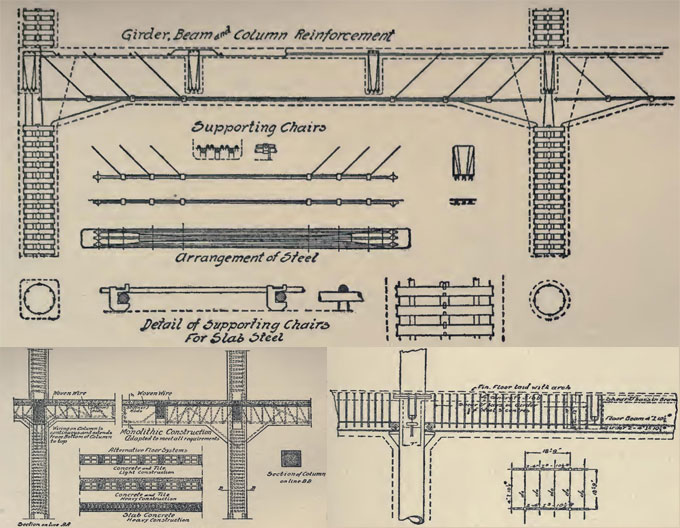

2. Column Reinforcement Work: After column location marking task, then the next step that comes is the placement of reinforcement as per the structural drawing.

The drawing description is as follows:

C1- 12#16 mm? and stirrup- 10 mm? @ 4? c/c.

This indicates column C1 will consists of 12 numbers of 16mm diameter bar as vertical bar and 10 mm diameter steel should be located 4 inch center to center as stirrup.

There is an alternate way too.

C2- 8#20 mm? + 10#16 mm? and stirrup- 10 mm? @ (4?+6 ?) c/c.

This C2 column?s reinforcement condition suggest that it will contain 8 numbers of of 20mm diameter bar along with 10 numbers of 16mm diameter bar as vertical reinforcement and (4??+6??) center to center of stirrups positioning indicates middle-half section of clear height of column will consist of 6?? center to center spacing of stirrups and upper one-fourth along with bottom one-fourth height of column?s clear height will hold stirrups at 4?? center to center spacing.

3. Column Formwork: During the building construction the floor height is usually maintained 10 feet. If the slab contains beam then concrete pouring takes place up to beam bottom level. Assume, beam height given in drawing is 1?-6??. So the casting will vary and it will be 8?-6??.

4. Concrete pouring into column: Casting column is simple. In case of small amount of concrete volume we generally count on machine-mix concrete and for large concrete amount we use ready-mix concrete. It is highly recommended to use machine-mix concrete. In case, if you use moving pump with ready-mix concrete and if you want not to surpass 5 feet height for the purpose of dropping concrete that would be really troublesome.