Details about Self-climbing Formwork

Self-climbing formwork is mainly undertaken because of the huge construction projects should be completed within scheduled time period.

Workplace safety is a vital concern for the implementation of self-climbing formwork techniques. These techniques are great substitutes for utilizing the cranes in construction sites. Workers will now work in an encircled secured atmosphere, and there is sufficient space for the tools and equipment.

A self climbing formwork arranges an operational platform on which the concrete forms are set, and the complete assembly is elevated with hydraulic cylinders. Each construction project comes with different characteristics, because of which the assemblies are generally adjusted to maintain their effectiveness and safety. Improved workplace safety, shortened construction period, and greater efficiency are some of the major benefits which self-climbing formwork techniques provide.

It is a very effective climbing system for skyscraper construction in building industry (high rise building cores like lift-shafts, stairwells and perimeter fa?ade walls) and large section piers and pylons in bridge construction.

This technique is very suitable for the locations where unskilled labor can?t be found sufficiently. In such systems, heavy machinery and high technology is not generally utilized. The method is technologically legitimate for nearly all types of buildings.

Formwork is applied similar to a mold where wet concrete is assigned temporarily. The temporary system operates as a provisional support for the structure. This method is a useful substitute for the traditional site based skills like timber formwork, masonry, and plastering. Carefully planned formwork results in enhancing the production, speed, and accuracy of the construction. Normally, in main housing schemes the cost of formwork is roughly up to 10 per cent of the general project price, and the time required is up to 60 per cent.

How Self-Climbing Formworks Are Assembled

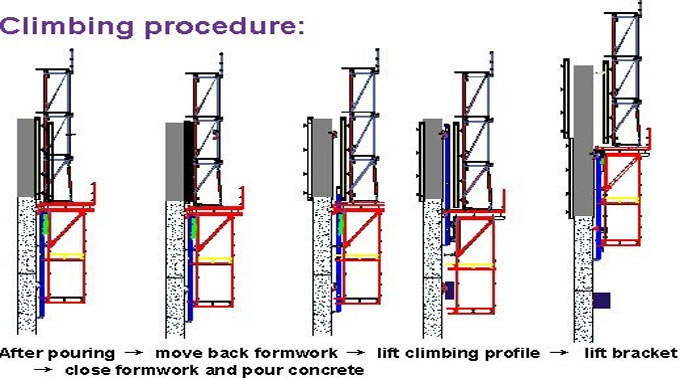

Generally, this type of formwork is developed from steel members. Concrete form panels are affixed to this frame; some of them supported on rollers. As soon as the concrete walls are poured, it is discharged and pulled away from the wall. Then, if self-climbing formwork is applied, jacks lift the frame up to the next level or to the next area where it will be utilized. It is considerably a very fast method.

After the climbing formwork set in exact position, the panels are closed, and then the next concrete wall is poured. The cycle carries on usually for three to five days. Though the process is very fast but the time may require for the construction of the floor slabs, which are poured as a separate process.